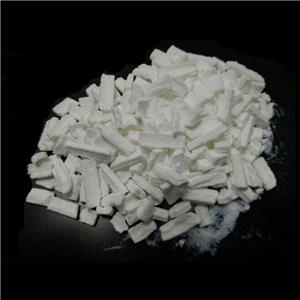

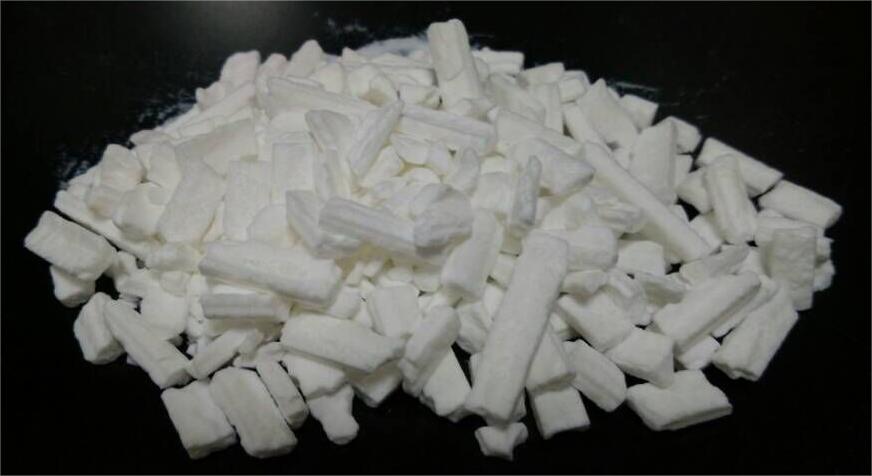

21MT/40HQ Precipitated Silica Granular Grade White Carbon Black for Rubber and Tires Industry

- SG-185

- Fujian

- 7-10days

- 100,000T/year

Usually, the loading capacity of precipitated silica powder is 18.5 tons of a 40-high cabinet, and the granular grade white carbon black produced by re-forging can be loaded to 21 tons of a 40-high cabinet, which can greatly save the international freight of customers.

In actual production, in order to meet specific application needs, powdered white carbon black is sometimes further processed into granular form.

For example, through the granulation process, adding an appropriate amount of binder in powdered precipitated silica or using mechanical extrusion, agglomeration and other methods, so that powdered precipitated silica particles aggregate with each other to form a larger granular structure, to improve its fluidity, reduce dust flying and other properties, and better adapt to some specific production processes and application scenarios.

Unique performance:

High specific surface area: granular precipitated silica has a large specific surface area, usually up to 100-400m ²/g or even higher. This makes it have good adsorption properties, can absorb a variety of gases, liquids and solid substances, in rubber, plastics and other fields as a reinforcing agent, can be fully in contact with the matrix material, increase the interface bonding force, improve the mechanical properties of the material.

High dispersion: After special processing, granular white carbon black can achieve good dispersion in various media. In the rubber mixing process, it can be uniformly dispersed in the rubber matrix to form a stable network structure, and effectively improve the physical properties and processing properties of rubber.

Good reinforcement: Due to its nanoscale particle size and high specific surface area, it can form a strong interaction with rubber molecular chains, and play a significant reinforcing role in rubber products, which can improve the tensile strength, tearing strength, wear resistance and other mechanical properties of rubber, making rubber products more durable.

Chemical stability: It has good chemical stability and is not easy to react in the general acid-base environment and most chemical substances. This enables it to maintain stable performance in application scenarios in different chemical environments and can be used in a variety of products that require chemical stability.

Optical properties: In some applications, granular white carbon black also has certain optical properties, such as good transparency and light scattering. In the fields of transparent rubber products and coatings, it can provide a certain hiding power and whitening effect, and maintain the transparency of products.