Wholesale White Carbon Black Powder Amorphous Precipitated Silica Fumed Silica SiO2 Hydrated Silica Rubber Usage Oxide Competitive

- SD-185P

- Fujian

- 7-10days

- 100,000T/year

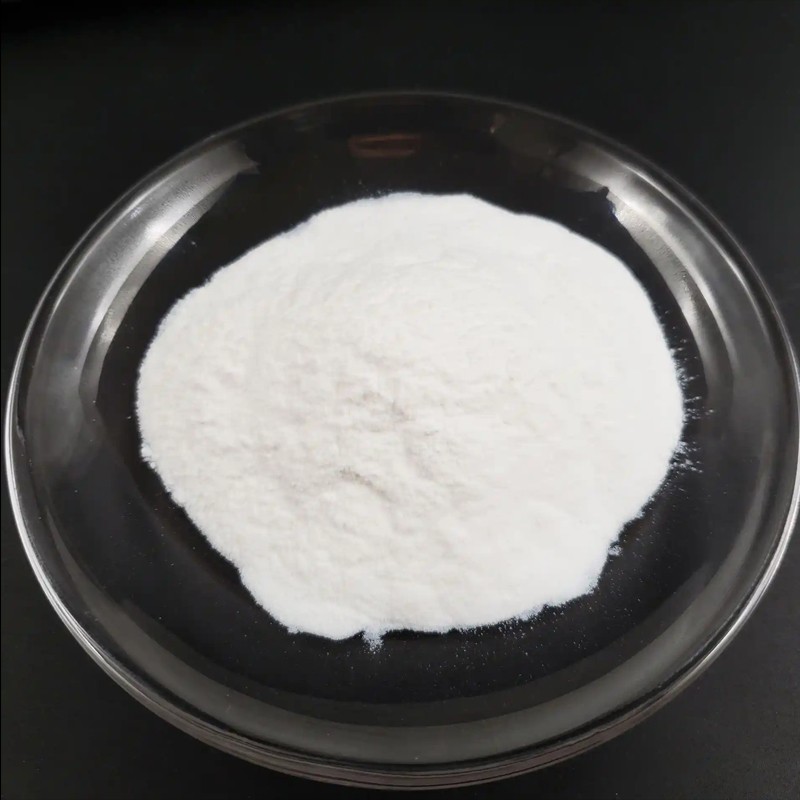

Xiamen Best Fortune supply SD-185P powder grade precipitated silica with high absorbability, makes it better reinforcement, suitable for filling rubber products, soles, tires, glue, conveyor belts and transmission belts, silicone tubes, etc., providing toughness and high wear resistance.

SD-185P powder grade precipitated silica is 18.5t/40HQ.

Tire Industry

Enhancing Wear Resistance: White carbon black powder has a high specific surface area and good dispersibility, which can closely combine with rubber molecules to form an effective reinforcing network. During the tire's running, it can enhance the wear - resistance of the tread rubber against road friction, reduce wear, and extend the tire's service life. According to tests, the wear - resistance of tires added with white carbon black can be increased by 20%-30% compared with traditional tires.

Reducing Rolling Resistance: The micro-structure of white carbon black helps to optimize the molecular arrangement of tire rubber and reduce the energy loss during tire rolling. Experimental data shows that the rolling resistance of tires using white carbon black can be reduced by 10%-20%, thereby reducing the fuel consumption of vehicles, achieving energy conservation and emission reduction, which is in line with the development trend of environmental protection and energy conservation.

Strengthening Wet Grip: Its hydrophilic surface can improve the contact between the tire and the wet road surface, enhance the tire's grip on wet roads, and improve the driving safety of vehicles. In the wet braking test, the braking distance of tires added with white carbon black can be shortened by 10%-15% compared with ordinary tires, effectively reducing the risk of traffic accidents in rainy days.

Rubber Industry

Improving the Strength of Rubber Products: In various rubber products such as rubber hoses, rubber belts, and seals, white carbon black powder, as a reinforcing agent, can significantly improve the tensile strength, tear strength, and fatigue resistance of rubber. For example, adding white carbon black to the rubber surface of conveyor belts can increase the tear - resistance strength of the conveyor belts by 30%-50%, enhancing their durability under harsh working conditions.

Enhancing Processing Performance: White carbon black helps to improve the mixing and molding processing performance of rubber. It can make it easier for rubber to disperse various compounding agents during the mixing process, improving the mixing uniformity. In the molding stage, it can reduce the viscosity of rubber, facilitate the molding operation, and improve production efficiency and product quality stability.

Strengthening Aging Resistance: White carbon black can form a protective film on the surface of rubber products, blocking the erosion of ultraviolet rays, oxygen, and ozone on rubber, delaying rubber aging, and prolonging the service life of rubber products. In rubber products used outdoors, such as rubber fenders and rubber seals, adding white carbon black can effectively improve their weather resistance and aging resistance.